During the completeness check it will be determined whether any parts that belong to a product are available. A possible check would be, for example, to check whether all balls are present in a ball bearing.

A completeness inspection is often associated with a position or location inspection.

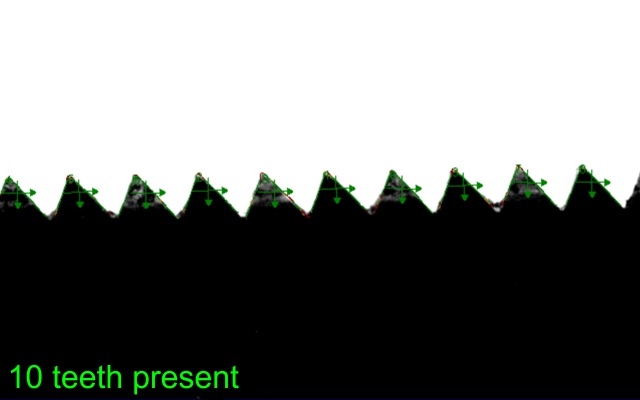

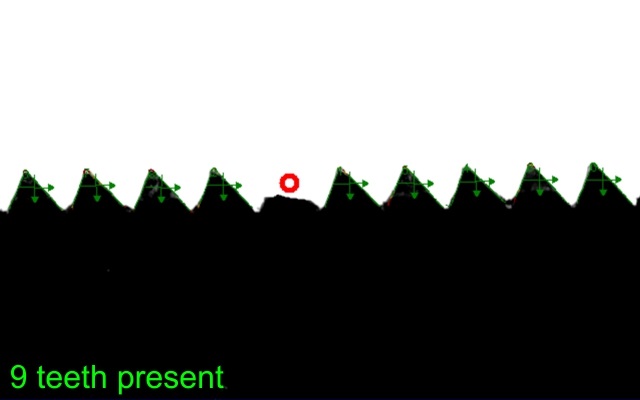

In the below product it will be determined whether any part of the teeth are complete. Broken teeth are automatically recognized by the system. It is possible to detect even slightest defects and so only one hundred percent correct parts will be delivered to customers. As indicated on the screen, only partially visible parts in the image are inspected with the used patented PatMax® technology (in this case a tooth), too.

Thread cutter

all toothes existing

one tooth is missing

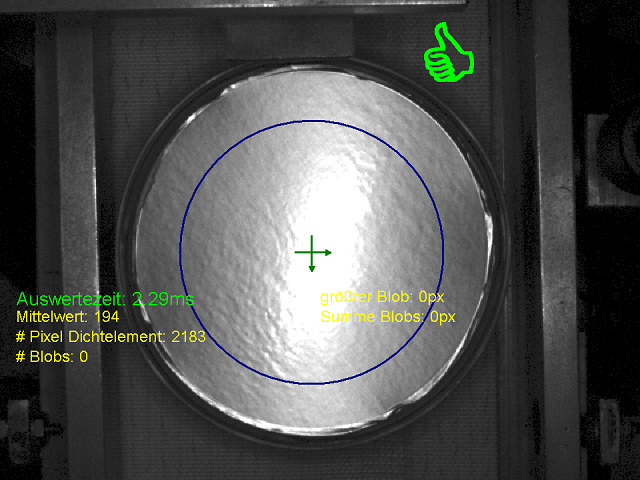

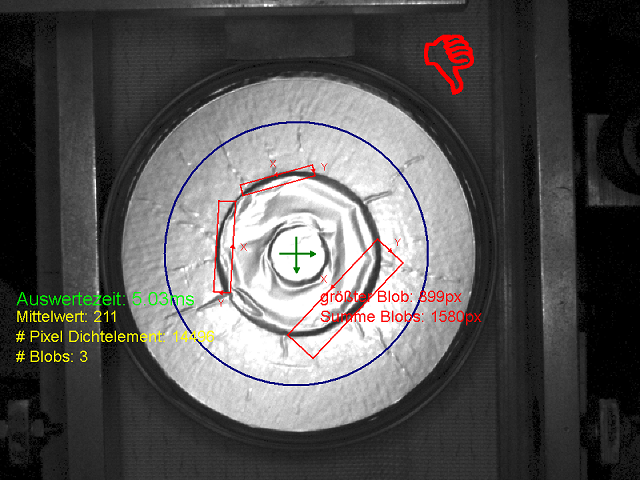

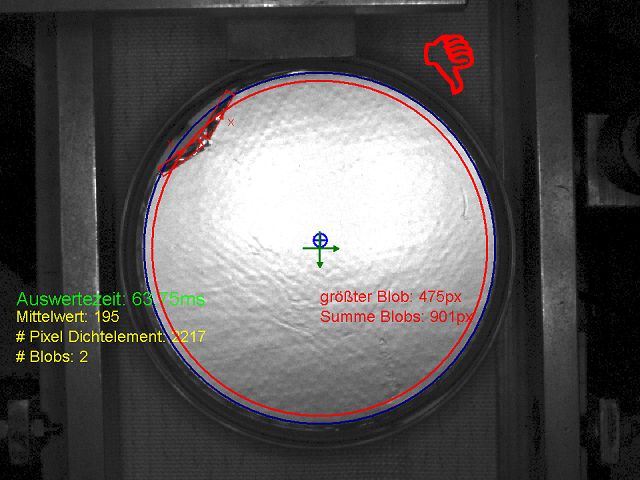

Cover foil / Lid of bottle

Cover foil OK

Cover foil NOK

Cover foil damaged