In many industries, deep learning expands the possibilities for automating industrial production and can solve numerous new applications that could not previously be automated. This includes reading demanding texts, checking surface defects, checking various assembly steps, classifying product quality and sorting variable parts.

Deep learning technology is used to predict patterns and perform judgment-based applications. This advanced technology deploys artificial intelligence (AI) algorithms to teach robots and machines to do what comes naturally to humans: learning by example. Cognex Deep Learning is designed for factory automation. Its field-tested algorithms are optimized specifically for machine vision, with a graphical user interface that simplifies neural network training without compromising performance.

Glass Breakage Inspection with Deep Learning and VisionPro

One of the most challenging tasks for image processing is glass breakage detection. Based on VisionPro with Deep Learning, we offer a system solution that is capable of detecting the smallest cracks in glass ampoules at a rate of up to 650 parts/min. Cognex VisionPro with Deep Learning is fully implemented in our KUPvision software and is very intuitive to operate.

Our new Camera Unit CCM101 with Ringlight and Model building with Deep Learning Studio

DL Training images:

Training images with result graphics

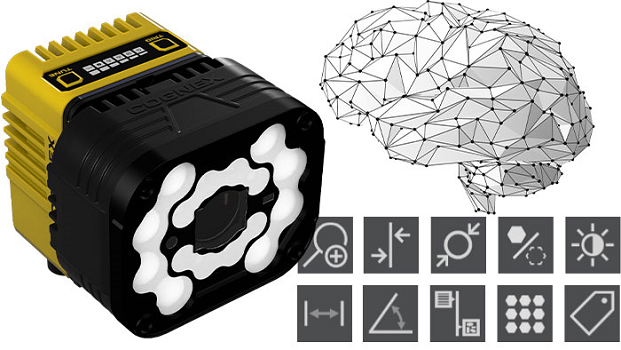

Edge Learning with In-Sight 2800

The In-Sight 2800 series combine artificial intelligence (AI) technology with traditional rule-based vision tools to solve a wide range of applications. From presence/absence detection to sortation and character reading, In-Sight 2800 provides an easy to deploy solution for error-proofing.

Edge Learning with In-Sight 3800

The In-Sight 3800 is all-in-one vision system and solves all your vision needs. Embedded with a full set of robust rule-based tools and innovative edge learning technology, In-Sight 3800 solves a wide range of manufacturing applications, from defect detection and assembly verification to character reading and more.

Deep Learning mit D900 Serie

The In-Sight D900 is a smart camera powered by In-Sight ViDi software designed specifically to run deep learning applications. This embedded solution helps factory automation customers easily solve challenging industrial OCR, assembly verification, and random defect detection applications anywhere on the line that have gone uninspected because they are often too difficult to program with traditional, rule-based machine vision tools.

In contrast to conventional image processing, which can be used excellently for products with the same appearance, deep learning is a new approach to industrial image processing. Deep learning uses neural networks for reading markings or texts, for error analysis and to localize and classify objects. For this purpose, images of flawless and, if necessary or desired, defective products are presented to the system for learning. Using examples, a neural network learns what a product should look like and can recognize the difference between a good and a defective part in the testing process, taking expected deviations into account.

Reading of difficult industrial OCR applications

Deep learning uses artificial intelligence and uses optical character recognition (OCR) to recognize, for example, badly deformed, crooked and poorly laser-etched characters on electronic components, needle-stamped characters on metal parts, embossed characters on injection-molded products, poorly legible texts on packaging and products or characters with little contrast that conventional OCR tools cannot decode.

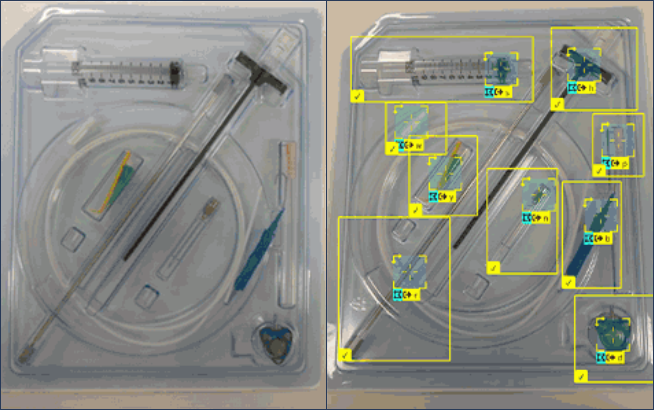

Quick and precise assembly checks

The artificial intelligence enables a reliable automated assembly check because even complex features and objects can be recognized. The system can be trained to build a comprehensive library of components that can be located in the image, even if they are visible at different angles or of different sizes.

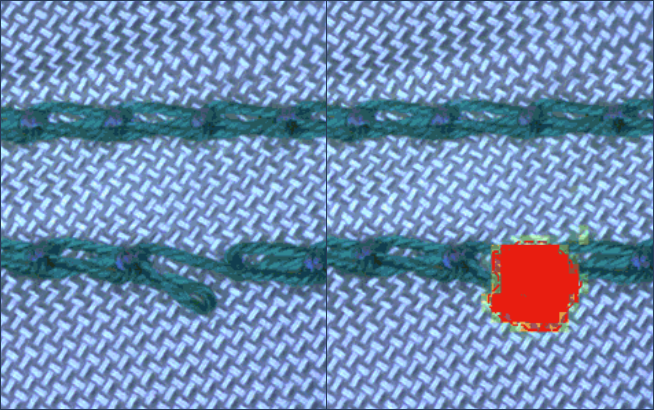

Identifies unpredictable errors

The deep learning system is suitable for finding anomalies on complex parts and surfaces, even in situations where the appearance of the defects can be unpredictable. The system is trained with images of faultless parts in order to identify image areas in the inspection process that deviate from the normal appearance, whereby defective parts can be recognized.