The In-Sight L38 is a next-generation 3D vision system that allows manufacturers to detect subtle features and measure them with high accuracy. The first-ever 3D vision system with embedded AI, the In-Sight L38 takes 3D applications beyond measurements to enable new types of inspections.

In-Sight L38

In-Sight L38 plugs

Powerful optics reveal fine details for better quality control

In-Sight L38 offers advanced optics on-device, with no external lighting required. Speckle-free and high-powered laser lines maximize contrast, even against challenging surfaces, and generate high-resolution images to improve the accuracy of automated inspections.

Patented, speckle-free laser reduces optical noise to create high-contrast images

AI and 3D technology deliver reliable inspection results

Using advanced AI and 3D imaging technology, the In-Sight L38 identifies subtle and variable features, and measures variances against defined tolerances. With each use, the embedded AI learns and adapts, improving the ability to detect even previously unseen anomalies to ensure continuous improvement and operational efficiency.

In-Sight 3D tools

Using a combination of powerful optics, industry-proven vision technology, and embedded AI, the system captures detailed 3D images and analyzes depth information to detect subtle features and measure them against pass/fail thresholds.

In-Sight Spreadsheet - unified software platform offers easy scalability

Flexible development options allow users to start with graphical training for simple applications and seamlessly transition to spreadsheet programming for more advanced applications. This unified approach ensures a seamless experience, allowing users to switch between the two interfaces and configure applications with ease.

In-Sight Vision Suite and Spreadsheet

Full suite of 2D and 3D tools meets a range of automation needs

Whether users need 3D depth perception for complex tasks or the simplicity and speed of 2D vision for standard applications, In-Sight L38 has both. The integration of 2D and 3D technology increases capabilities, while delivering detailed results, for flexible performance and reliable error-proofing.

Easy-to-use edge learning brings the power of AI to anyone

Edge learning is a subset of AI that uses a pre-trained set of algorithms to automate vision tasks in minutes. Training is simple, requiring as few as 5 to 10 images with no advanced programming or AI expertise needed. Powered by edge learning, ViDi EL tools deliver fast processing speeds to increase throughput, keep pace with operations, and deliver fast, reliable results in real time.

ViDi EL Segment (2D)

The ViDi EL Segment tool segments images to extract particular regions for targeted inspection. The region can include any type of feature on a part that users want to identify, from unwanted defects to critical components. Users train the tool by marking the region(s) of interest on an image and assigning it a class. After training just a few sample images, the tool learns to reliably segment the right features, even with varied parts and complex backgrounds.

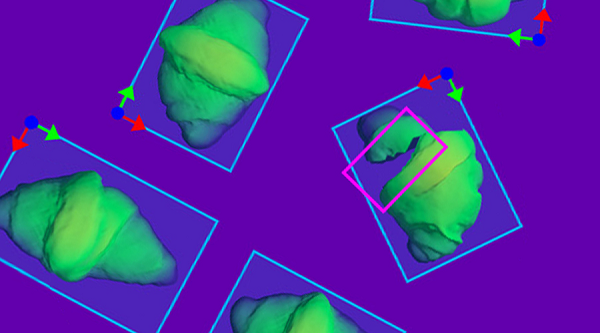

ViDi EL Segment (3D)

Advanced applications, such as those involving the detection and measurement of difficult-to-see defects, often require the use of multiple vision tools. In-Sight L38 easily solves these applications, with just one tool – 3D ViDi EL Segment. This tool detects challenging defects, gauges variances in three dimensions, and delivers results in real-world units to streamline workflows and deliver high reliability.

3D ViDi EL (Edge Learning)

Technical data