Most filling level inspections with in the imaging sector are present in the pharmaceutical industry or the food & beverage industry. In a filling level inspection it will be inspected whether all filling levels of a product have the correct value. Underfillings and overfillings can be detected.

Our systems allow to configure the inspection parameters after the desired requirements, so that overfillings can result only in a warning but not in a sorting out of the product. Needless to say, overfillings can also be detected and sorted out (depending on the customer's request).

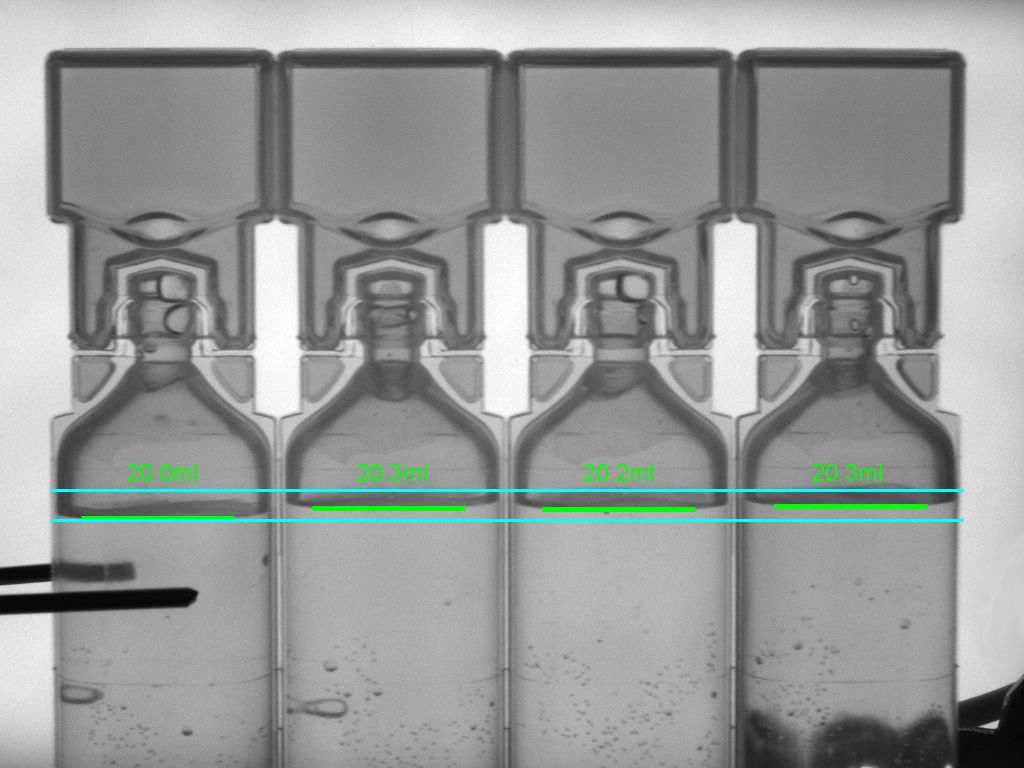

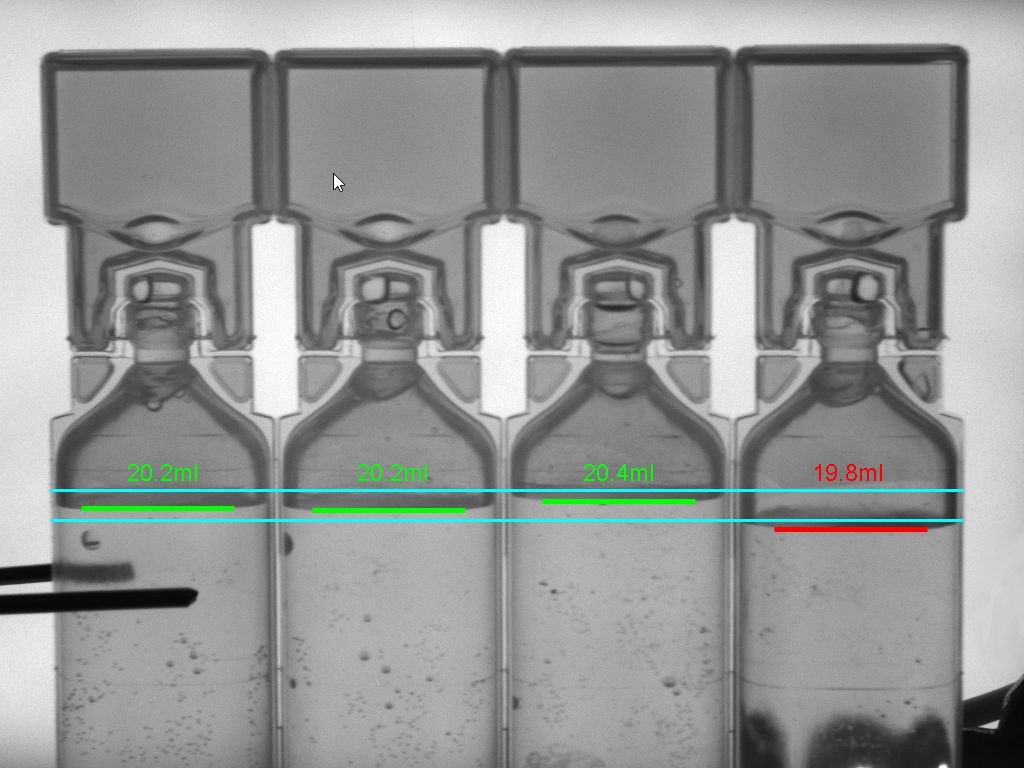

The following two pictures show the fill level inspection with four ampoules on a bottle pack. With the product illustrated here a level of 20ml for all ampoules is demanded. On the left image of the screen all flll levels are OK. On the right image the fill level of the fourth ampoule is not high enough and the product will be rejected from the production process.

All filling levels are OK

One filling level is to low