Surface inspections are used in all branches of the industry. It's used in the automotive industry on the inspection of painted vehicle parts or the pharmaceutical industry on the inspection of vials and ampoules. It is often necessary to detect defects that do not impair the function of a product but have a negative impact on the external impression of a product.

In the area of the surface inspection all kinds of materials are investigated (brass, plastic, glass, ceramics, paper etc.) on defects. Among the tests include the detection of cracks, flakings, dents, scratches and other.

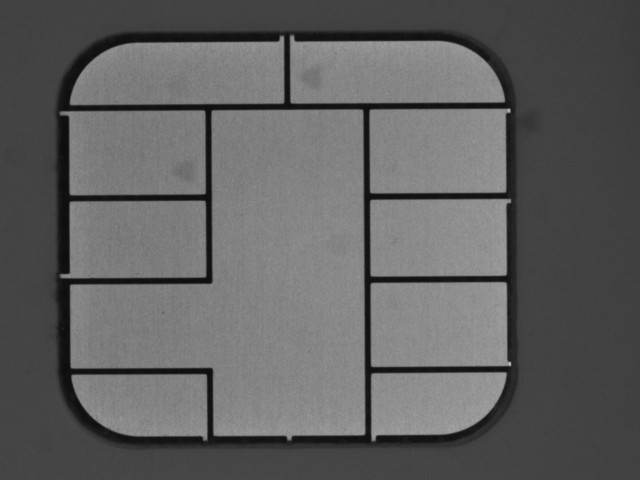

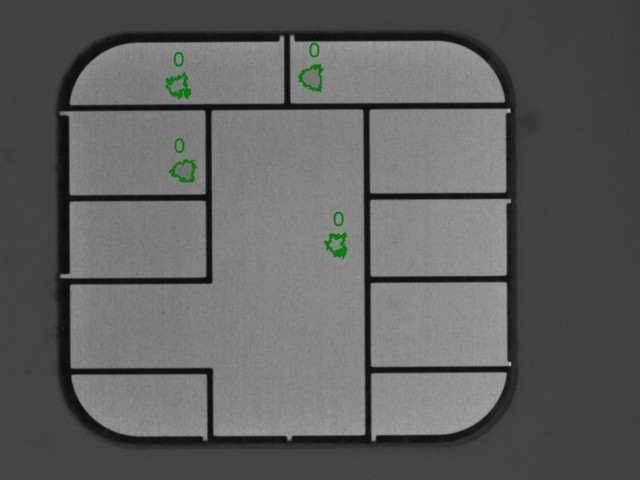

The following figures show the inspection of a module as it is often found on smart cards. On the left image is the product without an image analysis shown. In the right picture additionally also grease marks were found by using intelligent image processing routines.

Original image of the product

Product with found grease points