During the presence inspection, a product is checked for completeness. Usually, this happens right after an assembly step to remove incorrect parts from the production process or send it to a rework place as quickly as possible.

A presence inspection is a kind of completeness inspection. The product is complete, if the part which can be examined is present. Frequently a presence check is linked also with a position or location inspection.

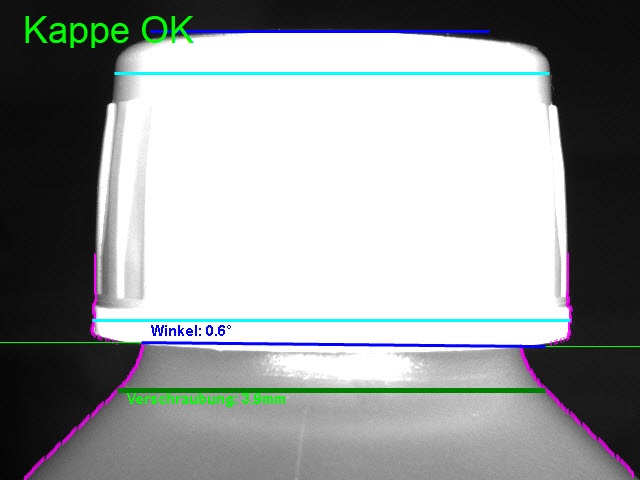

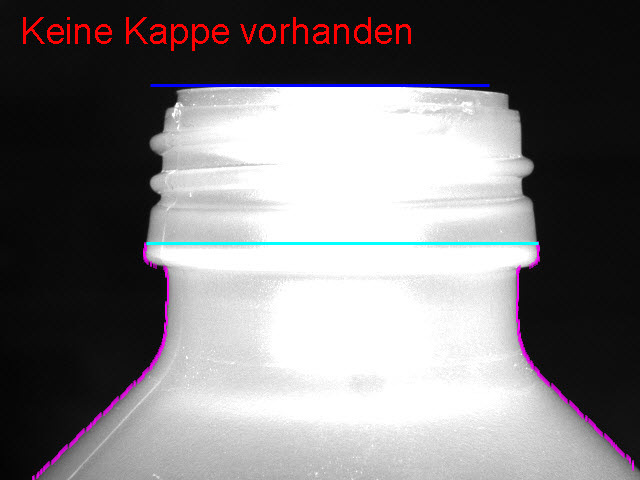

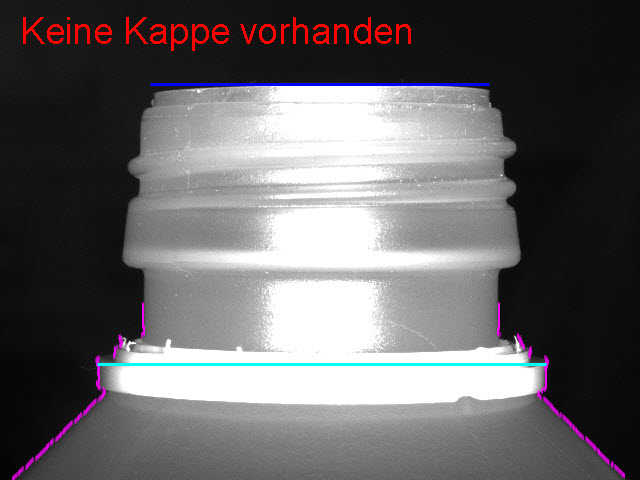

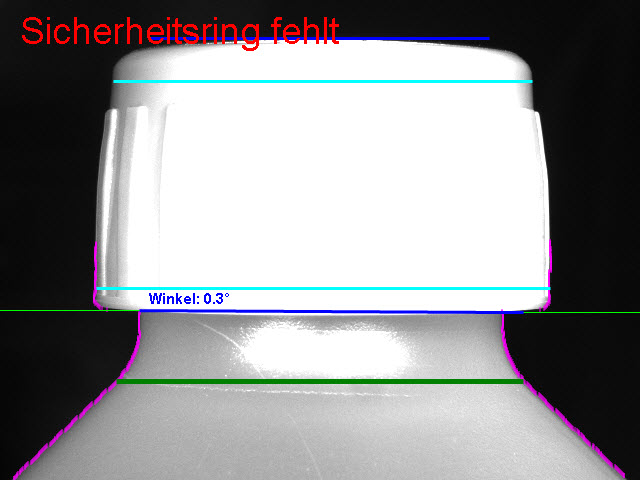

The following images show an example of a presence inspection of caps on plastic bottles.

Product is complete

No cap exist

Ring exists but cap is missing

Cap is not complete (no ring)

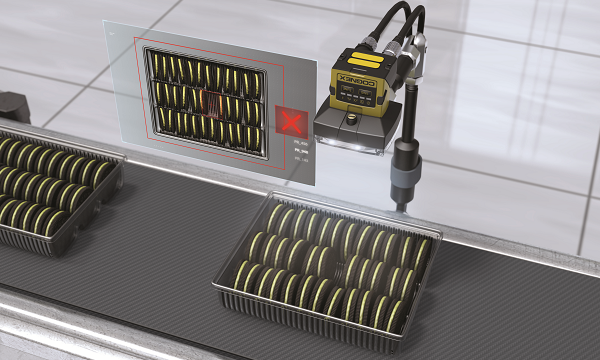

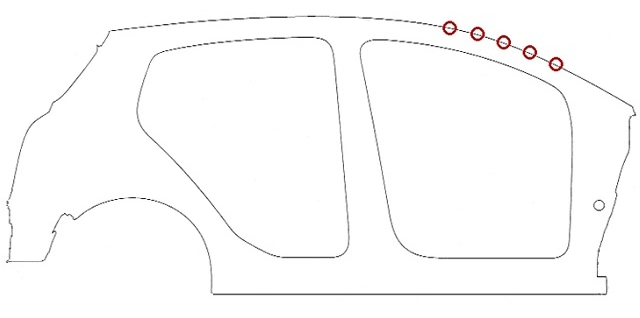

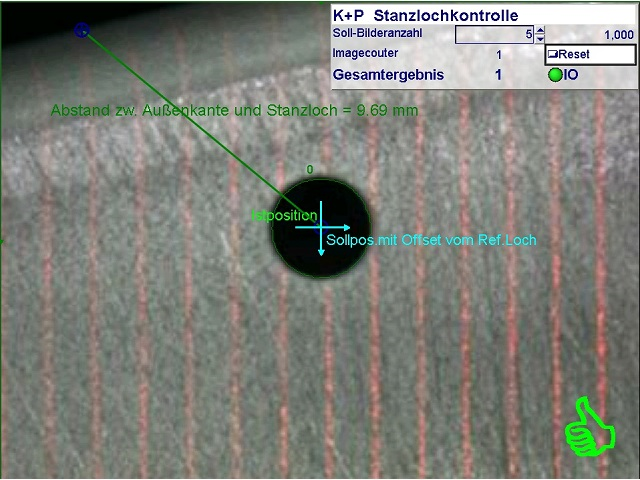

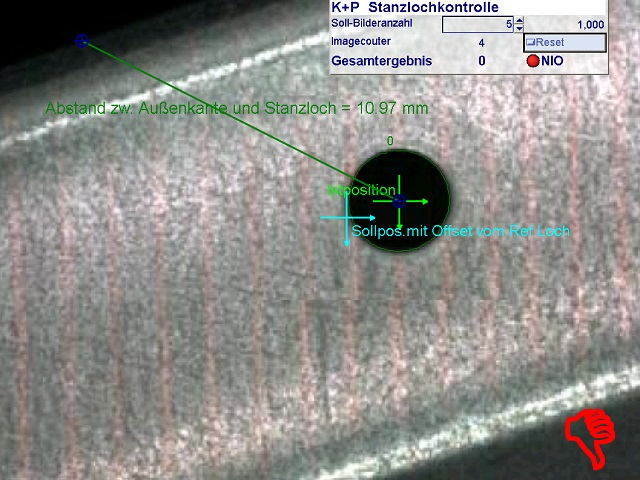

The following images show an example of an inspection of presence of holes in body side.

Body side with check positions

2D Image with punch hole (Position Pass)

3D Image with punch hole (Position Pass)

2D Image with punch hole (Position Fail)

3D Image with punch hole (Position Fail)

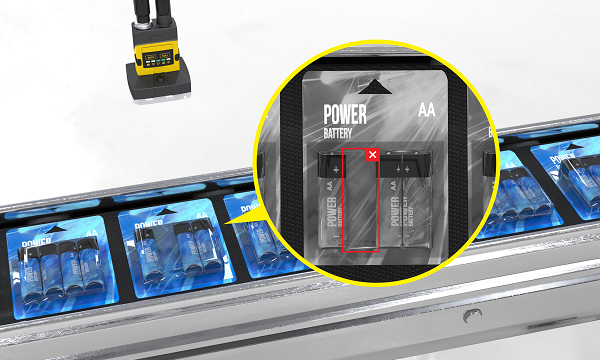

The following video shows a highspeed presence and print inspection done with a vision sensor.