In terms of sales, the automotive industry is by far the most important branch of industry in Germany. Hardly any other industrially manufactured mass product has changed the everyday life of mankind more than the automobile.

Since the invention by Carl Benz in 1885, there have been more than 2,500 companies producing automobiles. Many of them, who produced ironware or steel from the 19th century onwards, began producing weapons or bicycles towards the middle of the century. This enabled them to develop the necessary knowledge to become active in the automotive industry decades later.

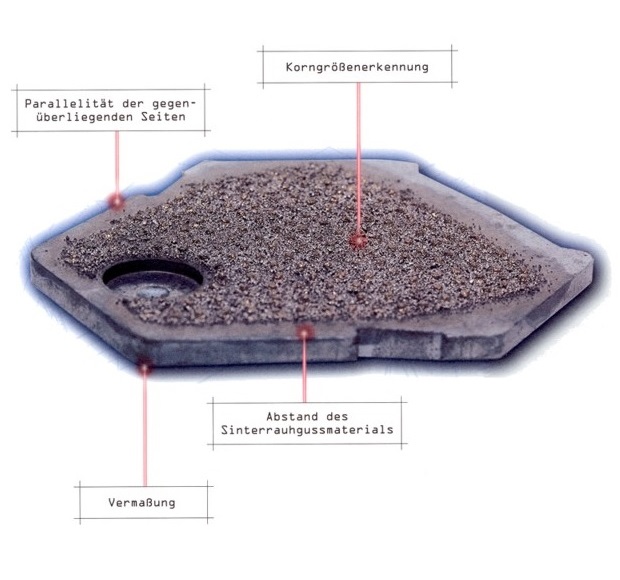

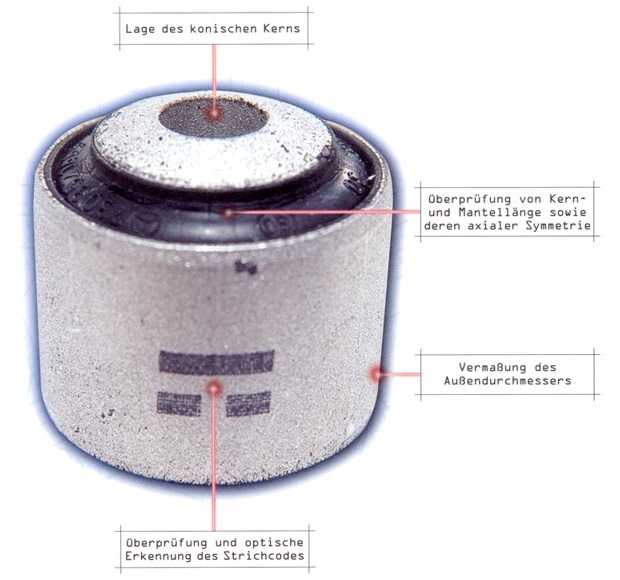

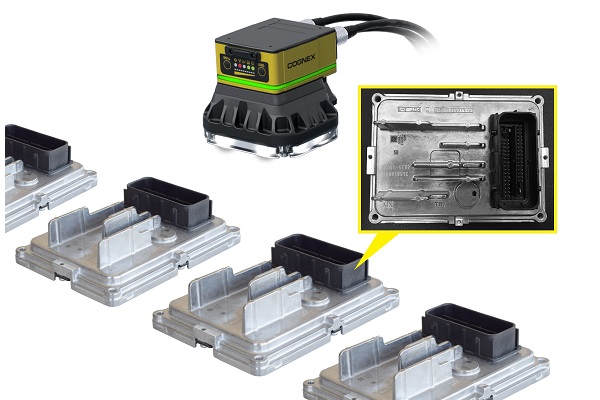

And this further development of knowledge is not yet complete. Almost every component in a vehicle can be improved using industrial image processing. Image processing and ID systems are used to test and identify assemblies and components in the manufacture and assembly of vehicles. From the punching unit to the body shop, from assembly to final inspection, the systems optimize product quality and reduce manufacturing costs.

Our inspection systems use fully automatic vision sensors or special vision systems systems, which can be operated comfortably and easily via our KUPvision software. Beside the mentioned inspection systems, Krempien+Petersen Qualitäts-Kontrollsysteme GmbH also offers the customized development of software and hardware.

Possible fields of application:

- Laser seam inspection on the car body

- Dimensional accuracy checks of different products

- OCV, OCR readings on different products and surfaces

- 1D and 2D code readings on different products and surfaces

- Presence inspections of different products

- Position and location detection of different products

- Surface inspections on different products

- Check for contamination on different products

- Inspection of injection moulded parts for completeness

- Sorting of different products

- Checking the cutting edges of air suspension tubes

- Pick and place applications

Gear module inspection

DMC reading

DMC reading

Color inspection

Presence and measurement