In the semiconductor and electronics industry, image processing systems are used for various inspections. Krempien+Petersen uses patented technologies from world market leader Cognex to solve these problems. To ensure that the correct components are used in assembly and placement, many components are provided with 1D or 2D codes. These parts can be automatically checked for correctness using ID readers. The use of ID readers also enables the traceability of all components.

Our inspection systems use fully automatic vision sensors or special vision systems, which can be operated comfortably and easily via our KUPvision software. Beside the mentioned inspection systems, Krempien+Petersen Qualitäts-Kontrollsysteme GmbH also offers the customized development of software and hardware.

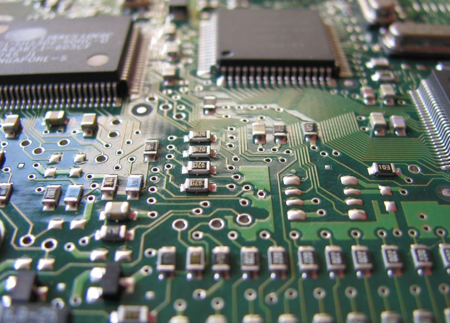

Possible fields of application

- Alignment of wafers

- Inspection of the wafers (e.g. damage or cracks)

- Completeness check of printed circuit boards

- Ensuring soldering quality

- Inspection of assembly and placement

- Labelling and verification of printed data

- Traceability solutions (Track & Trace)