The 3D-L4000 with VisionPro combines laser triangulation with advanced image formation to create highly-detailed, three-dimensional renderings of parts under inspection. From these topographical renderings, you can capture precise measurements of every surface-level feature including length, width, height, tilt, and volume.

3D-L4000

3D-L4000 plug-in connections

Better image formation in real-world settings

The 3D-L4000 with VisionPro includes patented, speckle-free blue laser optics that enable the system to capture higher quality images than traditional laser displacement sensors. This type of laser optics minimizes speckle and glare, common problems for 3D laser systems.

Speckle-free blue laser optics

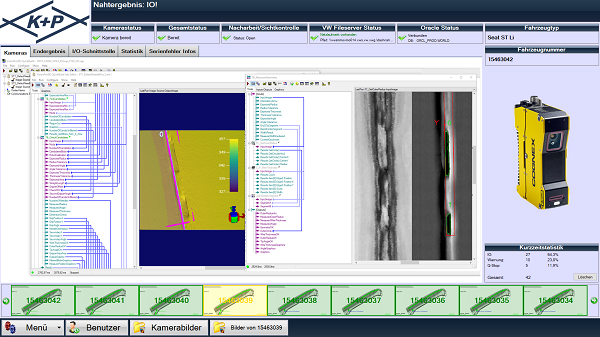

VisionPro with QuickBuild application and our KUPvision

The L4000 3D sensor, the VisionPro tools and the most important parameters are fully integrated into our KUPvision HMI software, which offers the customer a simple user interface including format and user management. KUPvision also includes the audit trail and all interfaces to the system technology.

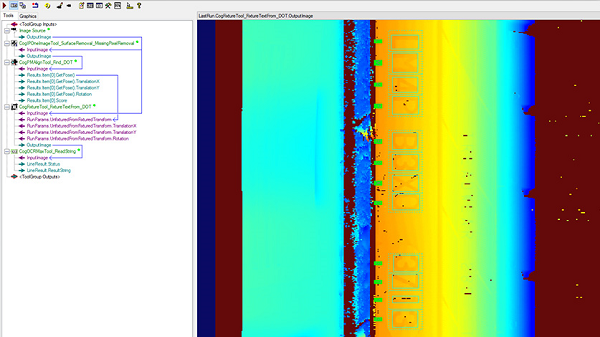

VisionPro application development

KUPvision HMI

Simplify complex applications without losing functionality

The 3D-L4000 laser displacement sensor is programmed using VisionPro software. VisionPro is a PC-based development environment that enables users to automate a wide range of functions, from inspection and identification to measurement and alignment. A full library of vision tools, combined with the intuitive QuickBuild interface, offers fast, flexible job configuration.

The easy-to-use QuickBuild interface provides a graphical approach to application development, allowing users to visually define and tune their application, without special programming or coding. Modular tool blocks allow users to create and reuse components, further simplifying setup and shortening cycle times.

VPro 3D-Tools

For more challenging vision tasks, the QuickBuild interface offers advanced scripting and provides .NET C# programming options for additional flexibility in building custom applications or manually configuring jobs by code. 3D-L4000 with VisionPro is also compatible with Cognex Designer.

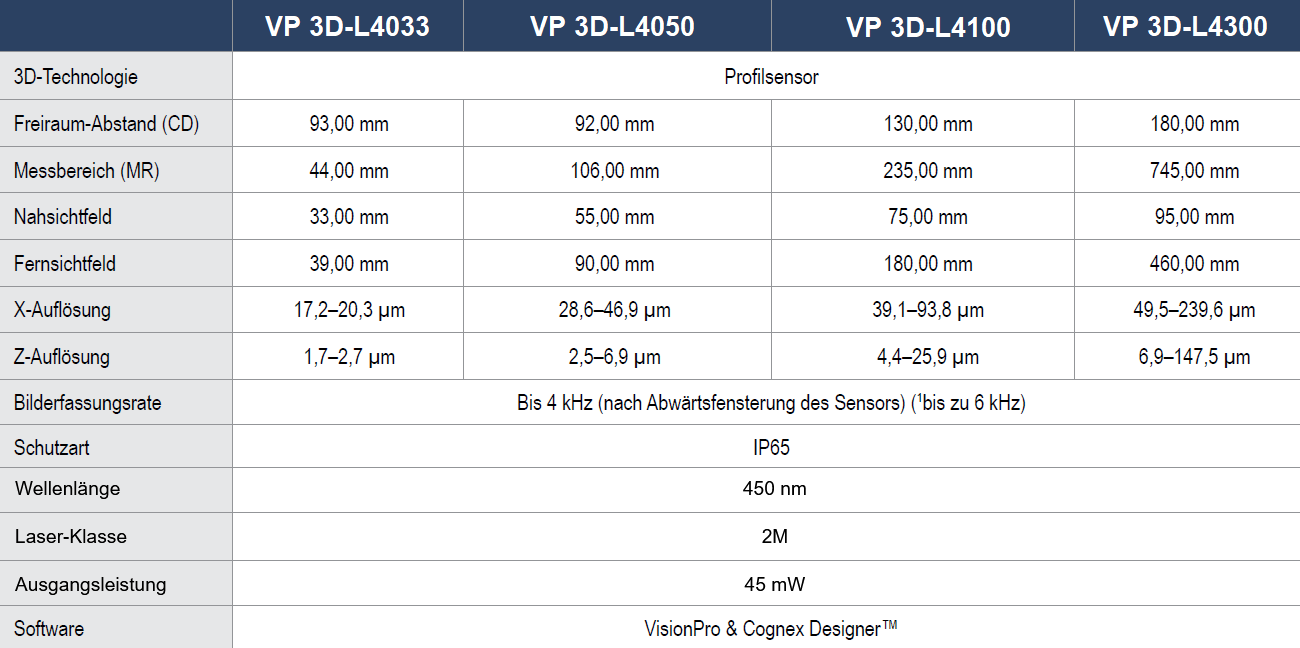

Technical data