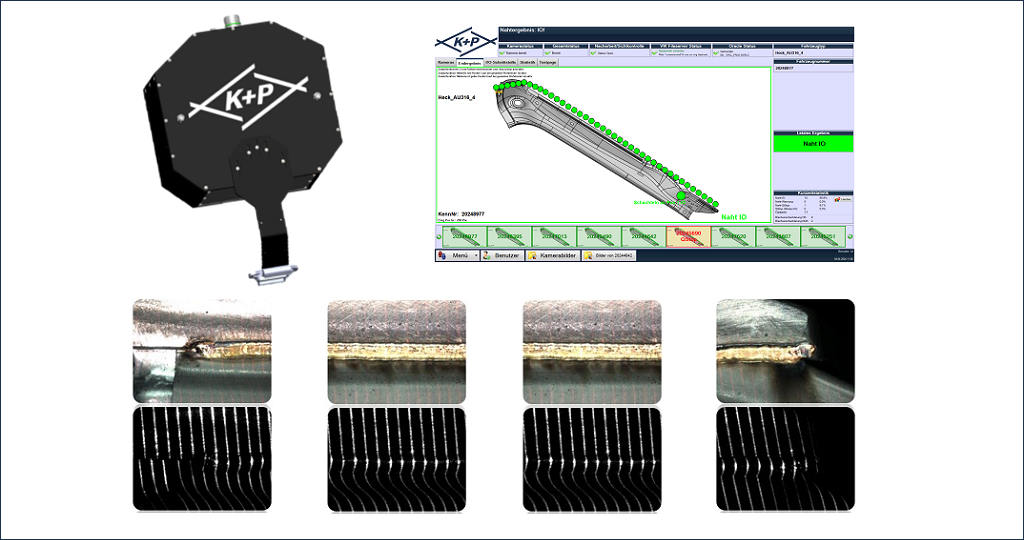

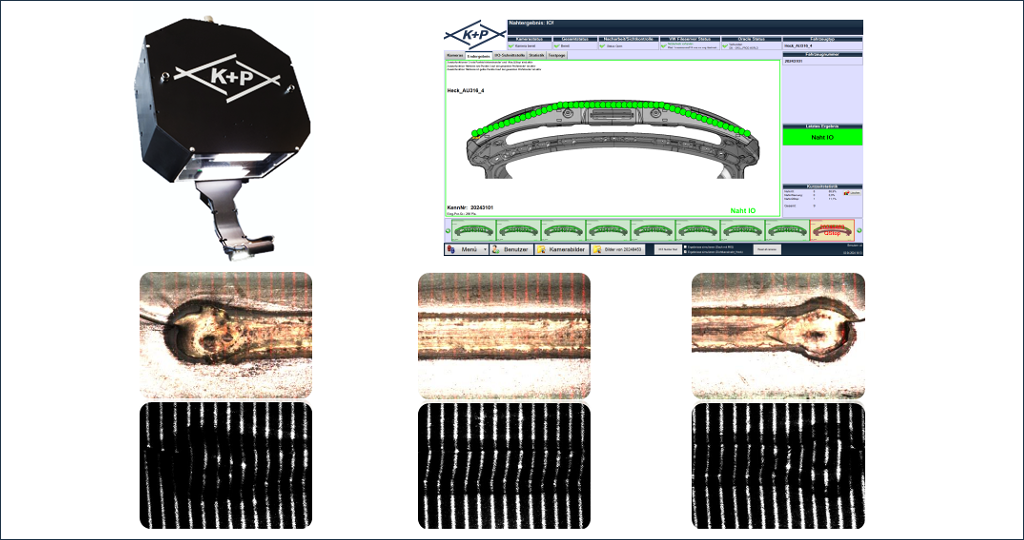

The Inspection of Laser soldered seam is an important process in the manufacturing industry to ensure the quality of soldered assemblies. By using our vision systems, automotive manufacturers can perform precise measurements and detect defects in real time. With a combination of 2D color analysis and 3D height profile measurement (triangulation method) in our vision systems, car manufacturers can produce more efficiently and reduce production costs. This advanced technology makes it possible to improve soldering quality and reduce rejects.

We offer the following successfully field-tested and implemented system solutions:

Why LSI system from K+P?

- Proven technology - robust hardware, standardized and very easy to use software KUPvision LSI

- 2D/3D technology - reliable detection, measurement and recognition of defects

- Extraneous light - absolutely independent of extraneous light influences

- Movement speed – up to 200 mm/s

- Interfaces - ProfiNet, Interbus, Oracle, FISeQS, FuQS, XML etc.

- Complete solutions - projects from one hand from the beginning to the system handover (turn key)

- Service - fast reaction times with good on-site support