The KPL50 was specially developed for applications such as laser solder seam inspection, where a lot of light is required in the tightest of spaces and where homogeneous illumination of the field of vision is as important as possible.

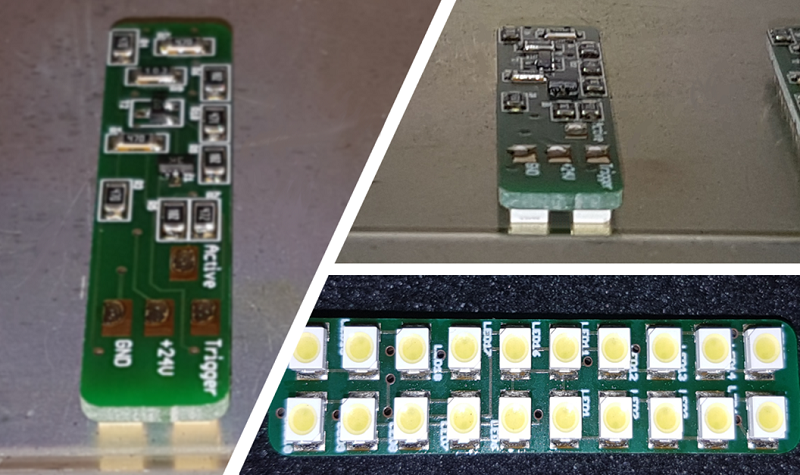

Due to the large number and tight placement of the SMD LEDs and the possibility of very short pulse times, an almost complete independence from extraneous light sources can be ensured. The acrylic glass window in front of the LEDs is replaceable so that the original image quality can be restored in case of contamination or damage.

KPL50 lighting for Laser soldered and CMT seam inspection

Circuit board production and final check

Features of KPL50

- High luminous intensity

- Very homogeneous light field

- 20 high-power SMD LEDs

- Replaceable acrylic glass window

- Direct control by the camera or sensorhead

- Flash operation in overcurrent range without reducing lifetime

- Flash duration between 16 μs and 1 ms

Technical data

- Operating voltage 24 VDC

- Self-current consumption max. 0.5 A (pulse current)

- Triggerlevel Low 0 ... ≤ 2.8 V

- Triggerlevel High 3.3 ... 35 V

- Operating temperature 0 to 45 °C

- Protection class IP 54

- Storage temperature - 40 to 85 °C

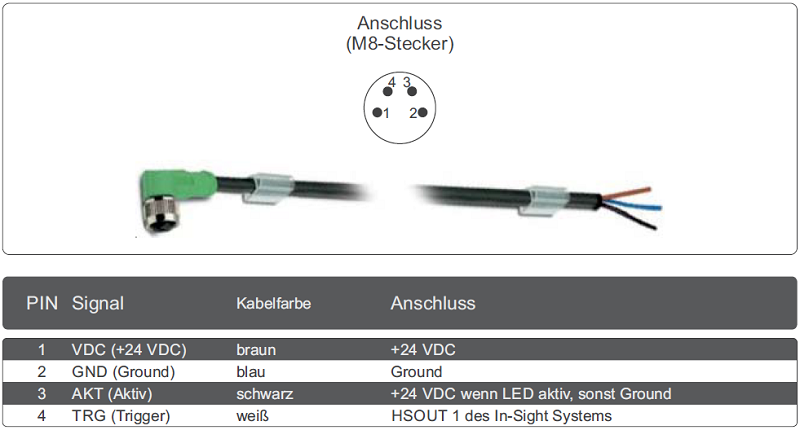

Pin assignment